Introduction to Thermodynamic Panels

Thermodynamic panels are designed to produce hot water for both domestic and commercial usage. These systems are more formally known as Solar Assisted Heat Pumps. This term helps to explain how and where this type of product fits into the renewable energy spectrum.

A thermodynamic panel is a halfway house between a solar panel and a heat pump. The primary purpose of this product is to provide heat energy in the form of hot water predominantly, but soon the systems will be adapted to provide space heatling (centeral heating) as well.

The products have been developed as a more efficient alternative to air source heat pumps by including the use of solar gain / radiation. This means that a thermodynamic system can benefit from both the ambient air temperature, like a heat pump, as well as the solar radiation, like a solar thermal system.

This best of both worlds approach will often result in an improved COP (coefficiency of performance). These products have been designed with a life expectancy of roughly 20 years by some manufacturers, however they have only really started to take hold in the UK over the last 6-8 years and Spain the last 2 years or so.

This best of both worlds approach will often result in an improved COP (coefficiency of performance). These products have been designed with a life expectancy of roughly 20 years by some manufacturers, however they have only really started to take hold in the UK over the last 6-8 years and Spain the last 2 years or so.

In early 2016 the first thermodynamic products were granted Microgeneration Certification Scheme (MCS) approval. This dramatically increased consumer and trade confidence.

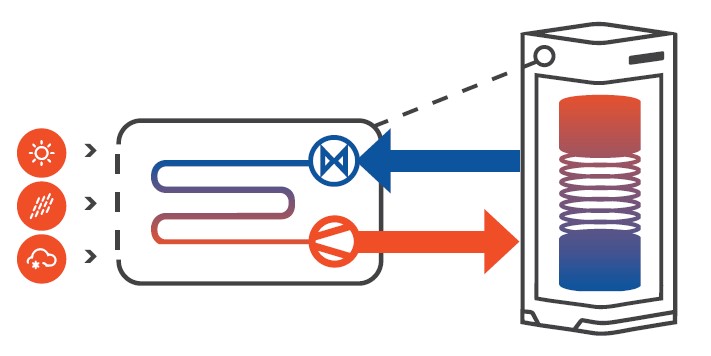

How does a TD system work?

A thermodynamic system works by sending a very cold liquid refrigerant around a panel on the outside of a property. The temperature of the liquid is approximately -22°C when it enters the panel. As the liquid flows through the veins in the panel it absorbs heat energy from the air surrounding the panel. This is where the term Thermodynamics comes from, as it is a scientific terms used to explain heat energy and its movements. The liquid refrigerant will vaporise into a gas once its temperature reaches approximately -15°C. This is more commonly known as its boiling point. The gas exits the panel and is circulated back to a compressor inside the thermodynamic unit. The compressor job is to compress the gas and send it under pressure through a heating element or plate. When a gas is compressed is gives off heat energy. The heating element is a way of distributing the heat into the store of water. Once the gas has lost its heat it exits the element and passes through an expansion value, which releases the pressure. This drop in pressure and loss of heat energy means that the gas condenses back to a liquid for the cycle to begin again.

The higher the temperature outside the more energy a thermodynamic system will be able to absorb, due to the greater heat difference between the liquid refrigerant and the air. Therefore the sun will help but it’s not essential. This means that thermodynamic panels can be positioned on a side wall of a property as well as a roof, and face any direction. However if possible it’s advised to position the panels towards the sun to gain that bit of extra performance. The panels will however continue to work at night time due to the heat being absorbed from the air.

The higher the temperature outside the more energy a thermodynamic system will be able to absorb, due to the greater heat difference between the liquid refrigerant and the air. Therefore the sun will help but it’s not essential. This means that thermodynamic panels can be positioned on a side wall of a property as well as a roof, and face any direction. However if possible it’s advised to position the panels towards the sun to gain that bit of extra performance. The panels will however continue to work at night time due to the heat being absorbed from the air.

The water inside the thermodynamic unit /cylinder is constantly monitored and kept hot by a thermostat. The thermostat will switch the system off once it reaches its required temperature. Most thermodynamic suppliers will set the stored water temperature of a domestic unit at 55°C. This is considered to be sufficiently hot for domestic hot water purposes, yet remaining safe for use. However, this temperature setting can be amended if necessary. Commercial units can be set at much higher temperature if needed.

What is a TD System made of?

A thermodynamics panel is roughly about the size of a standard door, 2m by 1m. The panels are made from anodised aluminium. The anodizing is an electrochemical process that converts the surface of the metal panel into a non-corrosive, durable finish. Inside the property / premises there would be a main unit. This unit consists of two sections, one of which holds the electronics and working parts, the other contains a water storage area. Thermodynamic units come in lots of different sizes dependent on the amount of water needed and storage capacity. Inside the unit you would find a compressor, circuit board, wiring, heating plate or element, expansion value and a backup immersion heater. Some units also come with a secondary coil built into the storage tank so that the existing boiler or additional heat source can be connected up. Most storage tanks within the units are made from stainless steel, however some come with enamelled cylinders. There is little difference between the performance of these cylinders, however stainless steel is often considered to be the more durable cylinder.

Types of TD Systems?

There are two main ways that a thermodynamic unit can be set up for a domestic property. The first is to install a small thermodynamic unit, usually no larger than 50cm by 50cm, which is designed to work with your existing hot water cylinder. The water from the standard hot water cylinder is pumped to the thermodynamic unit and is heated over a heating plate. These systems are idea if you are restricted on space, for example a tight airing cupboard. However because the water is heated externally from the cylinder a pump is needed which slightly increases the power consumed by the unit (manufactures quote between 300-450w when in use). These systems can be linked up with a maximum of about 250lt cylinder capacity. Be wary of installing these types of thermodynamic systems onto a vented hot water system (low pressure, with a header tank). When installing on a vented hot water system the position of the thermodynamic unit is very important, it must be sufficiently lower than the header tank to prevent low pressure air locks. A rare but not unusually problem, which can be easily fixed. In this instance the unit will turn off and display an error message or red light.

There are two main ways that a thermodynamic unit can be set up for a domestic property. The first is to install a small thermodynamic unit, usually no larger than 50cm by 50cm, which is designed to work with your existing hot water cylinder. The water from the standard hot water cylinder is pumped to the thermodynamic unit and is heated over a heating plate. These systems are idea if you are restricted on space, for example a tight airing cupboard. However because the water is heated externally from the cylinder a pump is needed which slightly increases the power consumed by the unit (manufactures quote between 300-450w when in use). These systems can be linked up with a maximum of about 250lt cylinder capacity. Be wary of installing these types of thermodynamic systems onto a vented hot water system (low pressure, with a header tank). When installing on a vented hot water system the position of the thermodynamic unit is very important, it must be sufficiently lower than the header tank to prevent low pressure air locks. A rare but not unusually problem, which can be easily fixed. In this instance the unit will turn off and display an error message or red light.

The second and more common thermodynamic system set up is to take out the existing cylinder and replace it with an all in one cylinder/thermodynamic unit. These units (example above) come in a range of sizes and cylinder capacities (75, 150, 160, 180, 200, 210, 250, 280, 300, 500lt). This set up is the most efficient way of installing and running a thermodynamic unit, if you have the space. The water is directly heated by a coil/element in the storage tank within the unit.

This means there is no heat loss from piping the water to an external heating unit. These systems can be fitted to both vented and unvented hot water systems. Quite often an old copper cylinder with poor lagging is replaced with the new thermodynamic unit, which means because of its modern insulation the heat is also retained more efficiently within the new cylinder. The larger 300lt & 500lt units are more commonly used for places with higher hot water demand, such as restaurants, B&Bs, hotels, hair dressers, farms etc…These larger units would often come with more panels, usually 2 or 4, which helps increase energy absorption and speed up recovery time. Manufacturers typically say that 200lt of water can be heated from normal tap water temperature up to 55°C in approximately 3-4 hours, but once achieved it is then constantly maintained.

Running cost of a TD System

The running cost of each thermodynamic unit is dependent on the size of the unit and compressor within, the volume of water being heated, the length of pipe run to the panels, the amount of hot water the property requires. Domestic systems will require between 300-450w of power when in use. An average domestic house would have approximately 200lt of storage capacity; this means that if the thermodynamic unit was running for 6 hours a day (2x complete fill & heating of 200lt tank) the unit would cost you approximately 30p. Most providers state that a typical house would expect to pay between €40-€60 per year in electrical running cost. Commercial units will typically range between €150-€500 per year to run, dependent on specific hot water requirements.

Maintenance, Warranties and Lifespan?

Thermodynamic systems do not need any maintenance. This is because they have very few moving parts and are a sealed system. Once the gas lines and panel/s have been correctly installed and filled with the refrigerant there should be no need to top up or maintain the system in the future. A qualified F-Gas engineer should vac down the entire system (suck all air out of the system) prior to inserting the refrigerant. This process removes imperfections such as particles of dust or water vapour, which could hamper the performance of the unit. Once the refrigerant is put into the system a pressure test should then be undertaken to determine the correct level of refrigerant needed and to check for any leaks. Due to the complexity and skill required to install a thermodynamic system correctly we recommend using a qualified F-Gas engineer.

Warranties for thermodynamic systems can vary from company to company from 2 year up to 5 years. Some companies will break their warranty down into different section, for example 2 years on labour and install, 2 years on the unit and 5 years on the panel. The best warranty we have found to date is a 5 year fully inclusive warranty. The most important thing to check is that the warranty is back up, either by the product manufacture or by an independent insurance provider. This will help to give you better protection if the company that sold you the thermodynamic system is no longer around in the future. The estimated lifespan of a thermodynamic system is around 25 years.

What are the Potential Savings of a TD System?

The savings for each individual thermodynamic system will widely vary, based on energy consumption, hot water consumption, location in the country and system set up. There are a few things you can do to maximise your systems performance, such as: Panels can be placed up to about 20m pipe run from the unit, however reducing this run can help save on the electrical running cost. If you can face the panels towards south in an open area you will also benefit from extra performance, due to solar gain. The average ambient air temperature will also play a part in the overall performance of each system. Someone living in Brighton would have high average air temperatures than someone in Edinburgh for example. This means that the unit in Brighton would absorb more heat from the air and recover the cylinder temperature faster, thus saving on the electrical running cost.

Despite these variances thermodynamic units appear to have a very low running cost, with manufactories displaying figures of 300w – 450w of electrical consumption when in use. This means that it would cost you between 3-4 pence per hour to run a thermodynamic unit. Systems typically only run for a few hours a day as when the water reaches temperature the unit will automatically turn off. Therefore the equation for working out savings would be as follows:

Domestic Hot Water Cost – Running Cost = Total Savings

The main variable in the equation is the domestic hot water cost. For some this is hard to decipher as it is all lumped into a gas, oil, electric or LPG bill. This will also vary based on the number of people in the property, hot water usage, boiler set up (combi or cylinder) and hot water system type (unvented or vented). Combi boilers will have a lower percentage of hot water on the bill compared to a cylinder system, as they only heat hot water on demand, whereas cylinders heat and maintain the entire water volume within. As an average guidance hot water can represent between 30-40% of a typical domestic properties fuel bill.

Thermodynamic Panel Mounting Methods

The most common and often cheapest way of installing a thermodynamic panel is to wall mount. This is achieved by using 6 stainless steel brackets that fix directly to an external wall.

The most common and often cheapest way of installing a thermodynamic panel is to wall mount. This is achieved by using 6 stainless steel brackets that fix directly to an external wall.

If multiple panels are needed for larger installations the thermodynamic panels can be racked. This is because they do not need sunlight to operated, and will work as long as there is sufficient air movement around the panels.

Thermodynamic panels can be installed onto a roof. This type of installation is very similar to how Solar PV panels are installed. Stainless steel runners will go along the roof for the panels to sit on and attach too. These runners are then attached to the joist via a metal clasp that slides under the tiles.

Panels can be installed on a flat roof using specially made a-frames. The panels must be louvered to a minimum of 15 degrees so that water can run off.

Panels can be installed on a flat roof using specially made a-frames. The panels must be louvered to a minimum of 15 degrees so that water can run off.